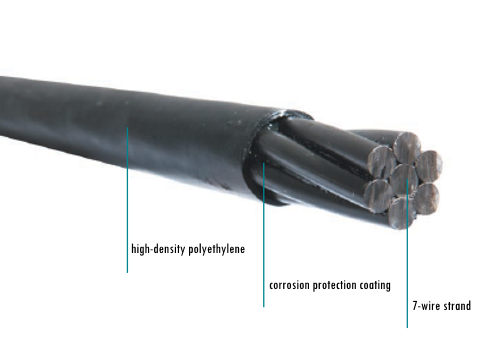

Seven wire smooth strand, covered in a suitable layer of anti-corrisive grease, HDPE coated with high-density poly-ethylene. This coating is an efficient protection against oxidation, allowing the strand to slide inside the HDPE cover.

It is used in plate post-tensioning and in pre-tensioned covering.

| Weight | Coil sizes | |||

|---|---|---|---|---|

| (Kg) | D (mm) | d (mm) | h (mm) | |

| ≤ 2700 | < 1420 | 900 | 760 | |

| Steel name | Nominal | Specified | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Diameter | Rm | Sn | M (steel only) |

Permitted deviation on mass per metre |

Fm | Fm,max | Fp0.1 | Agt | |

| mm | MPa | mm² | g/m | % | kN | kN | kN | % | |

| Y1860S7 | 12.9 | 1860 | 100.0 | 781.0 | ±2 | 186.0 | 214.0 | 164.0 | 3.5 |

| 15.2 | 1860 | 139.0 | 1086.0 | 259.0 | 298.0 | 228.0 | |||

| 15.7 | 1860 | 150.0 | 1172.0 | 279.0 | 321.0 | 246.0 | |||

| Characteristics | Test Method / Standards | Acceptance Criteria |

|---|---|---|

| Melt index | ISO 1133 10 min at 2.16 Kg |

≤ 0.25 g |

| Density | DIN 53479 | ≥ 0.95 g/cm³ |

|

Carbon black Content Disperson Distribution |

ISO 6964 ISO 4437 ISO 4437 |

2.3 ± 0.3% Index Max: C2 Index Max: 3 |

| Tensile strength (23ºC) | EN ISO 527-2 | ≥ 22 MPa |

|

Elongation At 23ºC At -20ºC |

EN ISO 527-2 EN ISO 527-2 |

> 600% > 350% |

| Thermal stability | ISO / TR 10837 | ≥ 20 min at 210ºC in O2 without degradation |

Note: Only applicable for black HDPE.

| Characteristics | Value | Norm |

|---|---|---|

| Cone Penetration 60 Strokes (1/10mm) | 250-300 | ISO 2137 |

| Dropping point | ≥ 150° C | ISO 2176 |

| Oil Separation at 40° C | at 72 hours ≤ 2.5 % at 7 days ≤ 4.5 % |

DIN 51817 |

| Oxidation Stability | 100 hours at 100° C ≤ 0.06 MPa 1000 hours at 100° C ≤ 0.2 MPa |

DIN 51808 |

|

Corrosion Protection 168 hours at 35° C 168 hours at 35° C |

pass no corrosion |

NFX 41-002 (salt spray) NFX 41-002 (distilled water spray) |

| Corrosion Test | grade 0 | DIN 51802 |

| Content of Aggressive elements Cl-, S2-, NO3- SO42- |

≤ 50 ppm (0.005%) ≤ 100 ppm (0.010%) |

NFM 07-023 NFM 07-023 |

Other specifications on request.

All kinds of pre-tensioning with wedge anchoring.

Some examples:

- Bars;

- Plates;

- Beams;

- Tubes;

- Pillars;

- Pre-tensioned panels.

Whenever required by the customer, manufacturing is done in conformity with any international standard, namely BS, ASTM, UNE, DIN, etc.